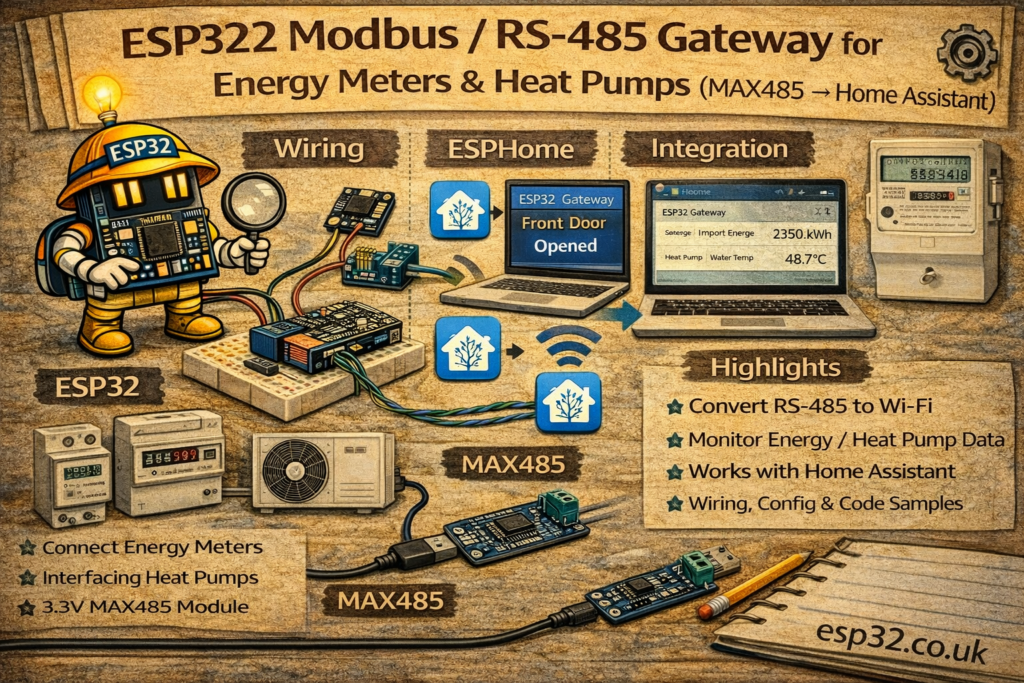

A huge amount of serious home energy hardware speaks Modbus RTU over RS-485:

- DIN-rail energy meters (e.g. SDM120, SDM630, DDSU666, etc.)

- Heat pumps, boilers, inverters, BMS controllers

- Industrial sensors and controllers

With one ESP32 and a cheap MAX485 (RS-485) transceiver, you can build a gateway that:

- Polls Modbus registers (voltage, current, power, kWh, temperatures, alarms)

- Publishes the values into Home Assistant

- Works fully local, no cloud

This guide covers:

- Wiring an ESP32 to RS-485 (MAX485)

- Modbus basics (address, baud rate, registers)

- ESPHome Modbus configuration (recommended)

- MQTT/Arduino alternative (optional)

- Practical tips for SDM120/SDM630 and heat pump integrations

1. Modbus RTU & RS-485 in 2 minutes

- RS-485 = physical layer (differential wires A/B, long distance, noise resistant)

- Modbus RTU = protocol running over RS-485

- One master (ESP32 gateway) polls one or more slaves (meter / heat pump)

- Slaves have:

- Address (1…247)

- Baud rate (commonly 9600)

- Parity/stop bits (often 8N1 or 8E1)

- Data lives in registers:

- Input registers (read-only)

- Holding registers (read/write)

- Values are often:

- 16-bit or 32-bit

- Scaled (e.g. “2305” means 230.5 V)

- Sometimes floats (IEEE 754)

2. Hardware Required

- ESP32 DevKit

- MAX485 module (or equivalent RS-485 TTL transceiver)

- RS-485 cable to meter / heat pump (twisted pair recommended)

- Optional: 120 Ω termination resistor (only at bus ends)

- Power supply for ESP32 (5 V USB is fine)

Important note about voltage levels:

- MAX485 modules typically run from 5 V (some are 3.3 V tolerant, many are not)

- The ESP32 UART pins are 3.3 V

- In practice, many MAX485 boards work with ESP32 without issues, but for “proper” engineering:

- Use a 3.3 V compatible transceiver (e.g. SP3485, MAX3485) or

- Ensure logic-level compatibility

If you want the safest choice: buy a MAX3485 / SP3485 “3.3 V RS485” module.

3. Wiring ESP32 ↔ RS-485 (MAX485)

MAX485 module pins typically:

- VCC, GND

- RO (Receiver Output)

- DI (Driver Input)

- RE (Receiver Enable) – active LOW

- DE (Driver Enable) – active HIGH

- A, B (RS-485 differential pair)

3.1 Recommended ESP32 Wiring (Half-Duplex)

Use one UART (example GPIO16/17) + one direction control GPIO:

ESP32 MAX485

----- ------

5V ---------------- VCC

GND ---------------- GND

GPIO17 (TX) --------- DI

GPIO16 (RX) --------- RO

GPIO4 ------------- DE and RE (tied together)

(DE=HIGH transmit, RE=LOW receive)

RS-485 A ------------ A

RS-485 B ------------ B

Direction control:

- Many libraries (and ESPHome) support a “flow control pin” to toggle transmit/receive.

- Often you connect:

- DE and RE together

- Drive them with a single GPIO

If your module labels RE as RE/ or ~RE, remember it’s inverted (active low).

4. RS-485 Bus Tips (Avoid Pain)

- Use a twisted pair for A/B

- Keep GND reference if possible (some devices need it)

- Termination:

- Only needed at long distances / high speed

- If used, place 120 Ω across A/B at the two ends of the bus

- Bias resistors:

- Some buses need pull-up/pull-down biasing (often built into equipment)

- If values are garbage:

- A/B swapped is common → just swap them and retry

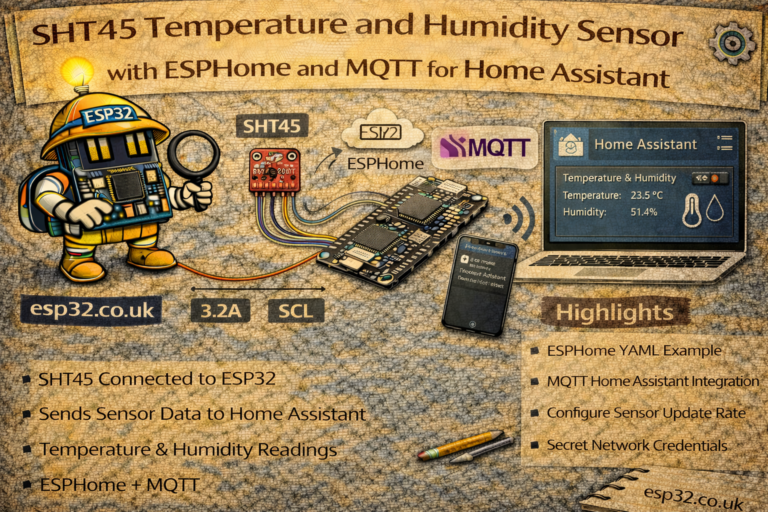

METHOD 1 — ESPHome Modbus Gateway (Recommended)

ESPHome can talk Modbus RTU and expose sensors directly into Home Assistant.

5. ESPHome Base Config + UART

esphome:

name: esp32-modbus-gateway

platform: ESP32

board: esp32dev

wifi:

ssid: "YOUR_WIFI"

password: "YOUR_PASSWORD"

logger:

api:

ota:

uart:

id: modbus_uart

tx_pin: 17

rx_pin: 16

baud_rate: 9600

stop_bits: 1

If your device uses parity (common on some meters), add:

parity: EVEN

6. Add Modbus Layer + Controller

modbus:

id: modbus1

uart_id: modbus_uart

flow_control_pin: 4 # DE/RE control pin

Now define a controller per slave address:

modbus_controller:

- id: sdm120

address: 1

modbus_id: modbus1

setup_priority: -10

update_interval: 5s

7. Example: SDM120 (Single Phase Meter)

SDM meters have well-known register maps (you’ll match to your manual).

Below is a typical pattern for voltage, current, power, energy (register numbers vary by model/firmware; verify in your SDM120 documentation).

sensor:

- platform: modbus_controller

modbus_controller_id: sdm120

name: "SDM120 Voltage"

id: sdm120_voltage

register_type: holding

address: 0x0000

unit_of_measurement: "V"

accuracy_decimals: 1

value_type: FP32

- platform: modbus_controller

modbus_controller_id: sdm120

name: "SDM120 Current"

register_type: holding

address: 0x0006

unit_of_measurement: "A"

accuracy_decimals: 2

value_type: FP32

- platform: modbus_controller

modbus_controller_id: sdm120

name: "SDM120 Active Power"

register_type: holding

address: 0x000C

unit_of_measurement: "W"

accuracy_decimals: 1

value_type: FP32

- platform: modbus_controller

modbus_controller_id: sdm120

name: "SDM120 Energy Import"

register_type: holding

address: 0x0156

unit_of_measurement: "kWh"

accuracy_decimals: 2

value_type: FP32

Key fields explained:

address:is the Modbus register addressregister_type:holding vs input (depends on device)value_type: FP32means 32-bit floatupdate_interval:in controller controls polling rate

If your meter uses input registers, change:

register_type: input

8. Example: SDM630 (Three Phase Meter)

You typically read per-phase voltage/current + total power + total energy.

Set controller address (example 2):

modbus_controller:

- id: sdm630

address: 2

modbus_id: modbus1

update_interval: 5s

Then define sensors similarly:

- Voltage L1/L2/L3

- Current L1/L2/L3

- Total active power

- Total import/export kWh

(Exact register addresses depend on your SDM630 map.)

9. Example: Heat Pump via Modbus

Heat pumps commonly expose:

- Flow temperature

- Return temperature

- Outdoor temp

- Compressor frequency

- Mode (heat/cool/dhw)

- Alarms

The structure is the same:

- Set the correct Modbus address, baud rate, parity

- Read registers based on the vendor map

- Apply scaling (sometimes ×0.1 or ×0.01)

If a register holds “235” meaning 23.5°C, you use filters:

filters:

- multiply: 0.1

Example:

sensor:

- platform: modbus_controller

modbus_controller_id: heatpump

name: "Heat Pump Flow Temp"

register_type: input

address: 0x0100

unit_of_measurement: "°C"

accuracy_decimals: 1

value_type: U_WORD

filters:

- multiply: 0.1

METHOD 2 — Arduino + MQTT Modbus Gateway (Alternative)

If you prefer “raw MQTT”:

- ESP32 reads Modbus registers with a library like ModbusMaster

- Builds JSON payload

- Publishes to MQTT topic like

home/modbus/sdm120

Example payload:

{

"voltage": 230.4,

"current": 1.82,

"power": 412.0,

"energy_kwh": 18.25

}

Home Assistant then uses the same mqtt: sensor: pattern you already use.

This method is flexible but requires more code and careful error handling.

10. Home Assistant Integration Ideas

10.1 Energy Dashboard

If you publish/import kWh correctly, you can feed Home Assistant’s Energy Dashboard (especially if you have solar / battery).

10.2 Alerts

- Notify if power draw exceeds a threshold

- Notify if heat pump reports an alarm register

- Notify if voltage drops below a safe level

10.3 Logging & Stats

Once data is in HA, it becomes part of:

- history graphs

- statistics

- long-term energy monitoring

11. Troubleshooting Checklist (Most Common Failures)

- A/B swapped: swap them if no response

- Wrong baud/parity: check device manual (9600 8N1 vs 9600 8E1 is common)

- Wrong slave address: many meters default to 1, but not always

- No direction control: ensure DE/RE pin is working if using MAX485

- Register map mismatch: SDM models differ; confirm addresses and data types

- Float word order: some devices swap 16-bit words (endianness). ESPHome supports different

value_typevariants if needed.

Summary

An ESP32 + RS-485 transceiver turns Modbus RTU devices into Home Assistant entities:

- Works for DIN energy meters like SDM120/SDM630 and many heat pumps

- ESPHome is the easiest path: UART + modbus + modbus_controller + sensors

- Once values are in HA, you can build dashboards, automations, and energy insights

The key is matching:

- slave address

- baud/parity

- register map + data type + scaling

Get those right and Modbus becomes one of the most powerful “serious hardware” integrations you can add to Home Assistant.